Improvement of the Paper Recycling Process through Enzymatic Refinement of Pulp

The impact of this project on our sector and society is multifaceted and overwhelmingly positive. By enhancing the quality of recycled paper and achieving properties comparable to those of paper made from virgin fiber, we reduce the need for limited natural resources and associated costs. A crucial aspect is that by not subjecting fibers to 100% mechanical refining, their deterioration is minimized, extending their lifespan. This allows for a greater number of fiber recycling cycles, promoting sustainability by reducing the constant need for new raw materials and decreasing the amount of waste generated.

This sustainable approach benefits not only Alier in terms of efficiency and competitiveness but also has a positive environmental impact. We contribute to the conservation of natural resources by reducing the demand for virgin fiber and prolonging the life of fibers. Furthermore, we promote environmentally friendly practices in the paper industry. Overall, this project represents a significant step towards sustainability, demonstrating our commitment to responsible resource management and environmental stewardship.

UTILITY OF THE FUNDS RECEIVED:

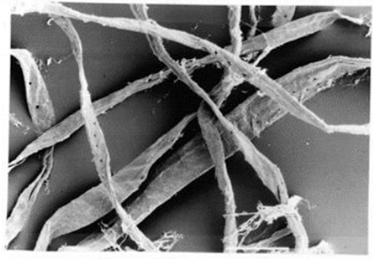

The approved budget covers a variety of key aspects for the success of the project. This includes covering the costs associated with the highly qualified personnel of the R&D and Quality departments, who will play key roles in the research and development of the new process. In addition, funds will be earmarked for the acquisition of specialized laboratory equipment, which will be indispensable for carrying out the necessary experiments and analyses. Consultation with the EURECAT technology center is also envisaged for the selection of enzymes, which will guarantee the efficacy and viability of the proposed biotechnological approach. Finally, resources will be allocated to subcontract microscopic fiber characterization tests, which will allow a detailed evaluation of the quality and properties of the fibers. Together, these investments will ensure an effective and successful implementation of the project.

PROJECT TIMELINES AND KEY PROJECT MILESTONES:

The project commenced in March 2021 with the initial phase dedicated to studying and selecting the most suitable enzymes for the process. This crucial stage laid the fundamental groundwork for the project’s development. Subsequently, in January 2022, the optimization phase of the enzymatic process at the laboratory scale began. Numerous experiments and tests were conducted during this phase to fine-tune and perfect the enzymatic process with the aim of maximizing its efficiency and effectiveness. Once this stage is completed, the validation of the process at an industrial scale is planned, involving the implementation and testing of the method under real production conditions. This phase is critical to ensure the viability and effectiveness of the process in an industrial environment. Finally, the project is expected to conclude in November 2024, marking the achievement of the established objectives and the successful culmination of the project.

CRITERIA AND METHODS FOR MEASURING PROJECT IMPACT:

Para evaluar el éxito del proyecto, se considerarán dos aspectos principales de manera integral. En primer lugar, se analizará el aumento en la fibrilación de las fibras como resultado del tratamiento enzimático. Este incremento en la fibrilación indica una mayor capacidad de las fibras para unirse entre sí, lo que se traduce en una mejora significativa en la resistencia del papel final. Además, se realizará una evaluación exhaustiva de las propiedades fisicomecánicas del papel resultante, buscando evidencia de mejoras cuantificables en términos de resistencia y durabilidad. Por otro lado, se examinará la disminución de los requerimientos en términos de potencia de refino para alcanzar la resistencia mecánica objetivo. Esta reducción en la potencia necesaria para refinar la pasta de papel indica una optimización eficiente del proceso, lo que se traduce en ahorros significativos de energía y recursos. En conjunto, estos criterios proporcionarán una evaluación completa y precisa del éxito del proyecto en términos de mejora de la calidad y eficiencia del proceso de fabricación de papel.

ESG: ENVIRONMENTAL

SDGS: 9, 12

Execution period: March 2021 to November 2024

Budget: €114,318

Grant: subsidy of 57,159 €.

File no.: arc035/21/000004

Government announcement: Adjustment improvement in processes applied in third party waste treatment plants, call for proposals 2021.

Agency: Waste Agency of Catalonia.

![]()